(1) Ukukhetha imishini engafanele.Lapho ukhetha izinto zokusebenza, umthamo omkhulu womjovo womshini wokubumba umjovo kufanele ube mkhulu kunesisindo esiphelele sengxenye yepulasitiki kanye nembobo, futhi isisindo somjovo esiphelele asikwazi ukudlula ama-85% wevolumu yokufaka ipulasitiki yomshini wokubumba umjovo.

(2) Isiphakeli esinganele.Indlela evame ukusetshenziswa yokulawula okuphakelayo yindlela yokuphakela kwevolumu engashintshi. Ivolumu yokuphakelayo kwerola kanye nosayizi wezinhlayiyana zezinto ezingavuthiwe kuyafana, nokuthi ingabe kukhona okwenzekayo "kwebhuloho" ngaphansi kwembobo yokuphakelayo. Uma izinga lokushisa embotsheni yokuphakelayo liphezulu kakhulu, lizophinda libangele ukwehla kwempahla embi. Mayelana nalokhu, imbobo yokuphakelayo kufanele ivulwe futhi ipholiswe.

(3) Ukungabi namandla kwezinto ezibonakalayo.Lapho uketshezi lwempahla eluhlaza kungenamsoco, imingcele yesakhiwo sesikhunta yisona sizathu esiyinhloko sokungajovi okwanele. Ngakho-ke, ukukhubazeka kokuma kwesistimu yokubunjwa kwesikhunta kufanele kuthuthukiswe, njengokusetha ngokunengqondo indawo yokugijima, ukunweba isango, umgijimi nosayizi wembobo yomjovo, kanye nokusebenzisa umlomo wombhobho omkhulu. Ngesikhathi esifanayo, inani elifanele lezithasiselo lingangezwa kufomula yezinto ezingavuthiwe ukuze kuthuthukiswe izindawo zokugeleza ze-resin. Ngaphezu kwalokho, kuyadingeka futhi ukuthi kubhekwe ukuthi ingabe izinto ezigaywe kabusha ezintweni ezingavuthiwe ziningi ngokweqile futhi zinciphisa ngokufanelekile inani lazo.

(4) Okokugcoba okweqile.Uma inani lokuthambisa kufomula yempahla eluhlaza liningi kakhulu, futhi igebe lokuguga phakathi kweringi yokuhlola isikulufu somjovo kanye nomgqomo likhulu, into encibilikisiwe izogeleza ibuyele kabuhlungu emgqonyeni, ibangele ukungondleki okwanele futhi kubangele umjovo ongaphansi. Mayelana nalokhu, inani lokuthambisa kufanele lincishiswe, igebe phakathi komgqomo nesikulufu somjovo kanye nendandatho yokuhlola kufanele ilungiswe, futhi izinto zokusebenza kufanele zilungiswe.

(5) Ukungcola kwezinto ezibandayo kuvimbela umzila wezinto ezibonakalayo.Uma ukungcola kwento encibilikisiwe kuvimbela umlomo wombhobho noma impahla ebandayo ivimba isango kanye nomgijimi, umlomo wombhobho kufanele ukhishwe futhi uhlanzwe noma imbobo yempahla ebandayo kanye nengxenye yomgijimi wesikhunta kufanele inwetshwe.

(6) Ukuklama okungenangqondo kwesistimu yokuthela.Uma isikhunta sinezimbotshana eziningi, ukubukeka kwamaphutha ezingxenyeni zepulasitiki kuvame ukubangelwa ukuklama okungenangqondo kwesango kanye nebhalansi yomgijimi. Lapho uklama uhlelo lokuthulula, qaphela ibhalansi yesango. Isisindo sezingxenye zepulasitiki emgodini ngamunye kufanele silingane nosayizi wesango ukuze umgodi ngamunye ugcwaliswe ngesikhathi esifanayo. Isikhundla sesango kufanele sikhethwe odongeni obukhulu. Uhlelo lokuklama lokuhlelwa kwebhalansi yomgijimi ohlukanisiwe lungabuye lwamukelwe. Uma isango noma umgijimi lincane, lincane, futhi lide, ukucindezelwa kwezinto ezincibilikisiwe kuzolahleka kakhulu phakathi nenqubo yokugeleza, ukugeleza kuzovinjelwa, futhi ukugcwaliswa okungalungile kungenzeka. Mayelana nalokhu, isigaba esiphambanayo sesiteshi sokugeleza kanye nendawo yesango kufanele kwandiswe, futhi indlela yokudla enamaphuzu amaningi ingasetshenziswa uma kunesidingo.

(7) Ukukhipha isikhunta esibi.Lapho inani elikhulu legesi elisele esikhunjeni ngenxa yokuphelelwa ngamandla licindezelwa ukugeleza kwezinto ezibonakalayo, okukhiqiza ukucindezela okukhulu kunokucindezela komjovo, kuzovimbela into encibilikisiwe ekugcwaliseni imbobo futhi ibangele ukujova ngaphansi. Kulokhu, kufanele kuhlolwe ukuthi ngabe imbobo yezinto ezibandayo isethiwe noma ngabe isikhundla sayo silungile. Ukuze uthole isikhunta esinemigodi ejulile, ama-grooves e-exhaust noma izimbobo zokukhipha kufanele zengezwe engxenyeni engaphansi komjovo; ebusweni besikhunta, i-groove yokukhipha ene-0.02 ~ 0.04 mm ukujula nobubanzi obuyi-5 ~ 10 mm ingavulwa, futhi imbobo yokukhipha kufanele ibekwe endaweni yokugcina yokugcwalisa emgodini.

Uma usebenzisa izinto zokusetshenziswa ezinomswakama owedlulele kanye nokuqukethwe okuguquguqukayo, inani elikhulu legesi nalo lizokhiqizwa, okuholela ekukhishweni kwesikhunta okubi. Ngalesi sikhathi, izinto zokusetshenziswa kufanele zomiswe futhi ama-volatiles kufanele asuswe.

Ukwengeza, mayelana nokusebenza kwenqubo yesistimu yesikhunta, ukukhishwa okungalungile kungathuthukiswa ngokwandisa izinga lokushisa lesikhunta, ukunciphisa isivinini somjovo, ukunciphisa ukumelana nokugeleza kwesistimu yokuthulula, ukunciphisa amandla okubamba, nokwandisa igebe lesikhunta.

(8) Izinga lokushisa lesikhunta liphansi kakhulu.Ngemva kokuba into encibilikisiwe ingene emgodini wesikhunta esinezinga lokushisa eliphansi, ngeke ikwazi ukugcwalisa wonke amagumbi omgodi ngenxa yokupholisa okusheshayo. Ngakho-ke, isikhunta kufanele sishiswe ekushiseni okudingwa yinqubo ngaphambi kokuqala umshini. Lapho umshini usanda kuqalwa, inani lamanzi okupholisa adlula esikhunjini kufanele lilawulwe ngendlela efanele. Uma izinga lokushisa lesikhunta lingakwazi ukukhuphuka, ukwakheka kwesistimu yokupholisa isikhunta kufanele kubhekwe ukuthi kunengqondo yini.

(9) Izinga lokushisa lokuncibilika liphansi kakhulu.Ngokuvamile, ngaphakathi kwebanga elifanele ukubunjwa, izinga lokushisa lempahla kanye nobude bokugcwalisa kuseduze nobuhlobo obuhle bokulinganisa. Ukusebenza kokugeleza kokuncibilika kwezinga lokushisa eliphansi kuncipha, okunciphisa ubude bokugcwalisa. Lapho izinga lokushisa lempahla liphansi kunezinga lokushisa elidingwa inqubo, hlola ukuthi ingabe okokuphakela imiphongolo kuqinile futhi uzame ukukhulisa izinga lokushisa lomgqomo.

Lapho umshini usanda kuqalwa, izinga lokushisa lomgqomo lihlala liphansi kunezinga lokushisa eliboniswa insimbi yokushisa imiphongolo. Kufanele kuqashelwe ukuthi ngemva kokuba umgqomo ushiselwe ekushiseni kwensimbi, kusadingeka upholiswe isikhathi esithile ngaphambi kokuba umshini uqalwe.

Uma umjovo wezinga lokushisa eliphansi udingeka ukuvimbela ukubola kwezinto ezincibilikisiwe, isikhathi somjikelezo womjovo singanwetshwa ngokufanelekile ukuze kunqobe umjovo ongaphansi. Ngemishini yokubumba umjovo wesikulufa, izinga lokushisa lesigaba esingaphambili somphongolo linganyuswa ngokufanelekile.

(10) Izinga lokushisa lombhobho liphansi kakhulu.Ngesikhathi sokujova, i-nozzle ihlangene nesikhunta. Njengoba izinga lokushisa lesikhunta ngokuvamile liphansi kunezinga lokushisa lombhobho futhi umehluko wezinga lokushisa mkhulu, ukuthintana kaningi phakathi kwakho kokubili kuzobangela ukuba izinga lokushisa lombhobho lehle, okuholela ekutheni into encibilikisiwe iqandiswe emlonyeni.

Uma kungekho mgodi wezinto ezibandayo esakhiweni sesikhunta, izinto ezibandayo zizoqina ngokushesha ngemva kokungena emgodini, ukuze ukuncibilika okushisayo ngemuva kungakwazi ukugcwalisa umgodi. Ngakho-ke, umlomo wombhobho kufanele uhlukaniswe nesikhunta lapho uvula isikhunta ukuze kuncishiswe umthelela wokushisa kwesikhunta kuzinga lokushisa lombhobho futhi ugcine izinga lokushisa ku-nozzle ngaphakathi kwebanga elidingwa inqubo.

Uma izinga lokushisa lombhobho liphansi kakhulu futhi lingakwazi ukukhushulwa, hlola ukuthi i-heater yombhobho yonakele yini bese uzama ukukhulisa izinga lokushisa lombhobho. Uma kungenjalo, ukulahlekelwa kwengcindezi yezinto ezigelezayo kukhulu kakhulu futhi kuzodala umjovo ongaphansi.

(11) Ukucindezela komjovo okunganele noma ukucindezela kokubamba.Ukucindezela komjovo kuseduze nobuhlobo obuhle bokulinganisa nobude bokugcwalisa. Uma ingcindezi yomjovo incane kakhulu, ubude bokugcwalisa bufushane futhi i-cavity ayigcwaliswa ngokugcwele. Kulokhu, ingcindezi yomjovo inganyuswa ngokunciphisa isivinini sokuya phambili komjovo futhi kunwetshwe ngokufanelekile isikhathi somjovo.

Uma ingcindezi yomjovo ingakwazi ukukhuphuka ngokuqhubekayo, ingalungiswa ngokwandisa izinga lokushisa lempahla, ukunciphisa i-viscosity encibilikayo, nokuthuthukisa ukusebenza kokuncibilika kokuncibilika. Kuyaqapheleka ukuthi uma izinga lokushisa lempahla liphezulu kakhulu, izinto ezincibilikisiwe zizobola ngokushisa, ezithinta ukusebenza kwengxenye yepulasitiki.

Ngaphezu kwalokho, uma isikhathi sokubamba sisifushane kakhulu, sizophinde siholele ekugcwaliseni okunganele. Ngakho-ke, isikhathi sokubamba kufanele silawulwe ngaphakathi kwebanga elifanele, kodwa kufanele kuqashelwe ukuthi isikhathi eside kakhulu sokubamba sizophinde sibangele amanye amaphutha. Ngesikhathi sokubunjwa, kufanele kulungiswe ngokuya ngesimo esithile sengxenye yepulasitiki.

(12) Ijubane lomjovo lihamba kancane kakhulu.Ijubane lomjovo lihlobene ngqo nesivinini sokugcwalisa. Uma isivinini somjovo sihamba kancane, into encibilikisiwe igcwalisa isikhunta kancane, futhi into encibilikisiwe egeleza ngesivinini esiphansi kulula ukupholisa, okwehlisa kakhulu ukusebenza kokugeleza kwayo futhi kubangele ukujova ngaphansi.

Kulokhu, ijubane lomjovo kufanele lenyuswe ngendlela efanele. Kodwa-ke, kufanele kuqashelwe ukuthi uma ijubane lomjovo lishesha kakhulu, kulula ukubangela amanye amaphutha okubumba.

(13) Ukwakheka kwesakhiwo sengxenye yepulasitiki akunangqondo.Lapho ubukhulu bengxenye yepulasitiki bungalingani nobude, ukubunjwa kuyinkimbinkimbi kakhulu futhi indawo yokubumba inkulu, into encibilikisiwe ivinjelwa kalula ekungeneni kwengxenye encane enezindonga zepulasitiki, okwenza kube nzima ukugcwalisa umgodi. Ngakho-ke, lapho uklama ukwakheka kwesakhiwo sengxenye yepulasitiki, kufanele kuqashelwe ukuthi ubukhulu bengxenye yepulasitiki buhlobene nobude bokugeleza komkhawulo wezinto ezincibilikisiwe ngesikhathi sokugcwalisa isikhunta.

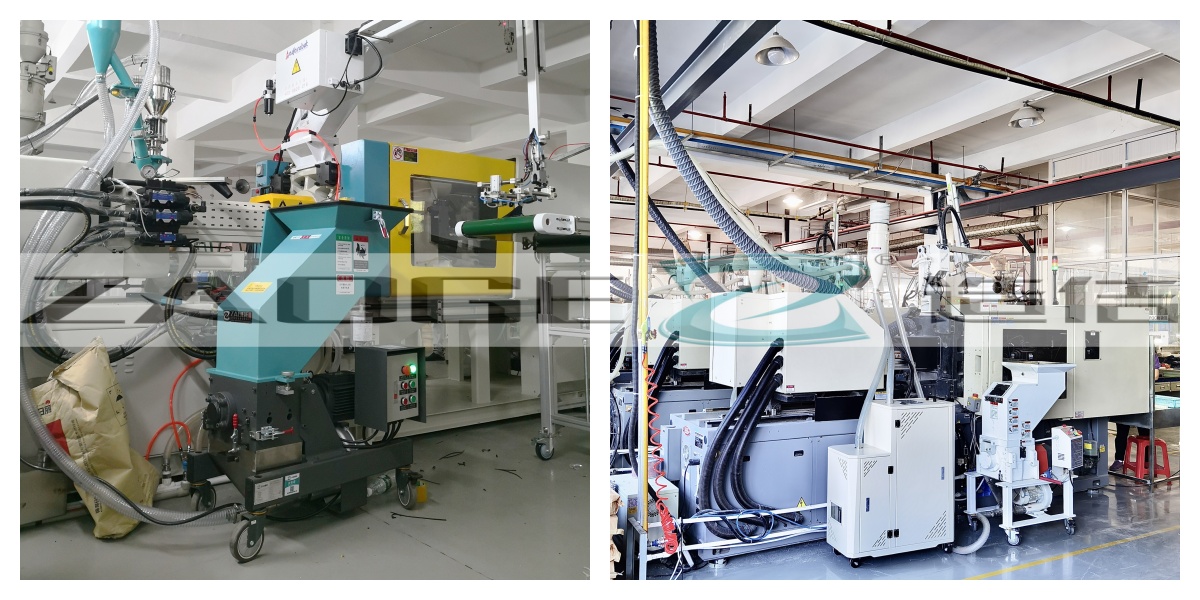

Ngakho-ke singamane sisebenzise kabusha kanjani kalula futhi ngempumelelo impahla yokugijima ekhiqizwe umshini wokubumba umjovo?ZAOGE'silungelo lobunikazied inline ukuchotshozwa okushisayo okusheshayo kanye nekhambi eliphezulu lokugaywa kabusha okusheshayo. To lawula kangcono ikhwalithi yomkhiqizofuthiintengo. Laboizinto ezichotshoziwe ziyiyunifomu, zihlanzekile, azinalo uthuli, azingcolisi, ikhwalithi ephezulu, zixutshwe nezinto ezingavuthiwe ukukhiqiza imikhiqizo yeqophelo eliphezulu.

Isikhathi sokuthumela: Jul-10-2024