Ama-Granulator E-Plastiki amathathu-in-One

Incazelo

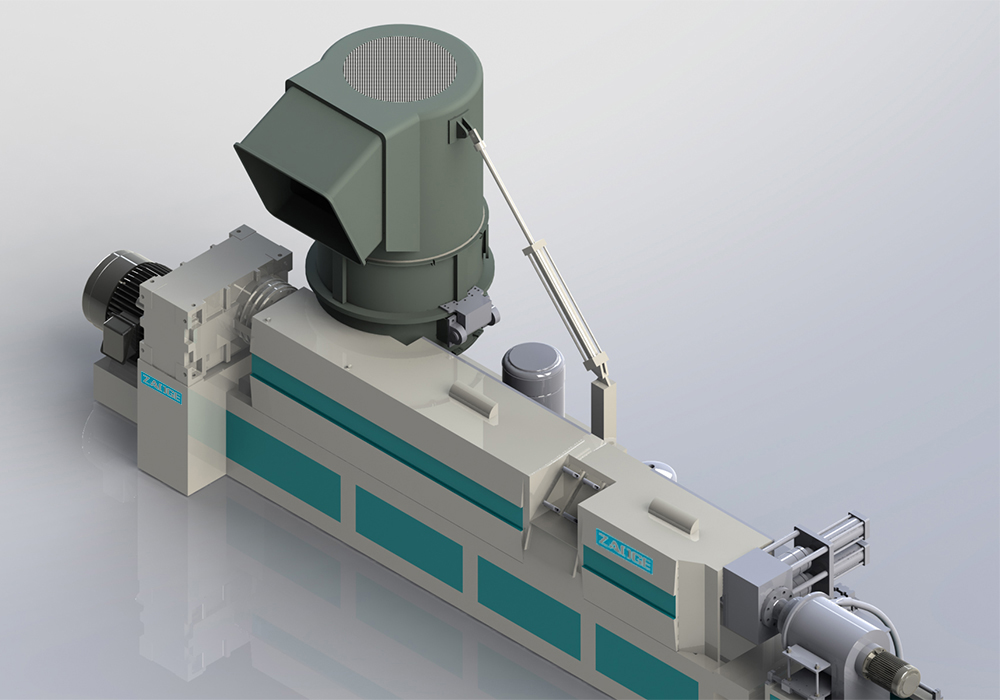

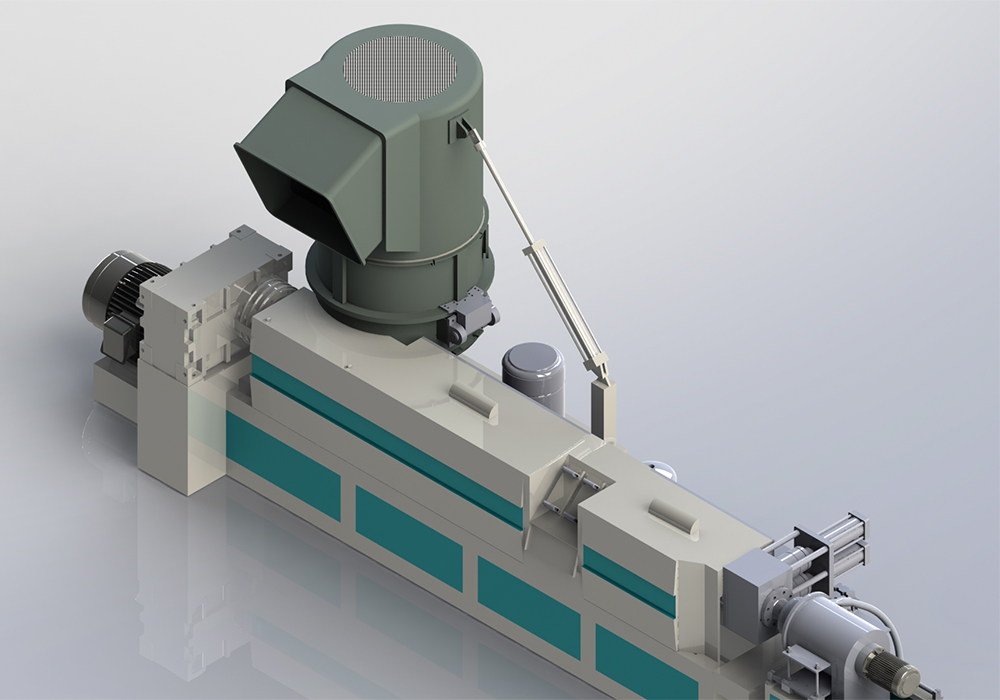

Le mishini ifanele i-PP, i-OPP, i-BOPP, i-HDPE, i-LDPE, i-LLDPE, i-ABS, i-HIPS namanye ama-Granulators okuvikela imvelo epulasitiki. Ukwamukela injini enciphisa amandla yaseJalimane, ukonga amandla afika ku-20%; imishini emithathu kokuchotshozwa, extruding, futhi Plastic Granulators, bafe ukusika ngaphandle idivayisi amanzi ithangi, isikhala esincane sokusetha; ukwamukela ukuguqulwa kwesikrini se-hydraulic esingami ikholomu ephindwe kabili, ukusebenza okulula nokulula, okulungele ukuthuthukisa ukusebenza kahle kanye namandla okukhiqiza.

Incazelo

Le mishini ifanele i-PP, i-OPP, i-BOPP, i-HDPE, i-LDPE, i-LLDPE, i-ABS, i-HIPS kanye nezinye i-pelletizing yokuvikela imvelo yepulasitiki. Ukwamukela i-German reducer motor, ukonga amandla asebenzayo afika ku-20%; imishini emithathu kokuchotshozwa okukodwa, ukukhipha kanye ne-pelletizing, ukusika ukufa ngaphandle kwedivayisi yethangi lamanzi, isikhala esincane sokusetha; ukwamukela ukuguqulwa kwesikrini se-hydraulic esingami ikholomu ephindwe kabili, ukusebenza okulula nokulula, okulungele ukuthuthukisa ukusebenza kahle kanye namandla okukhiqiza.

Imininingwane eyengeziwe

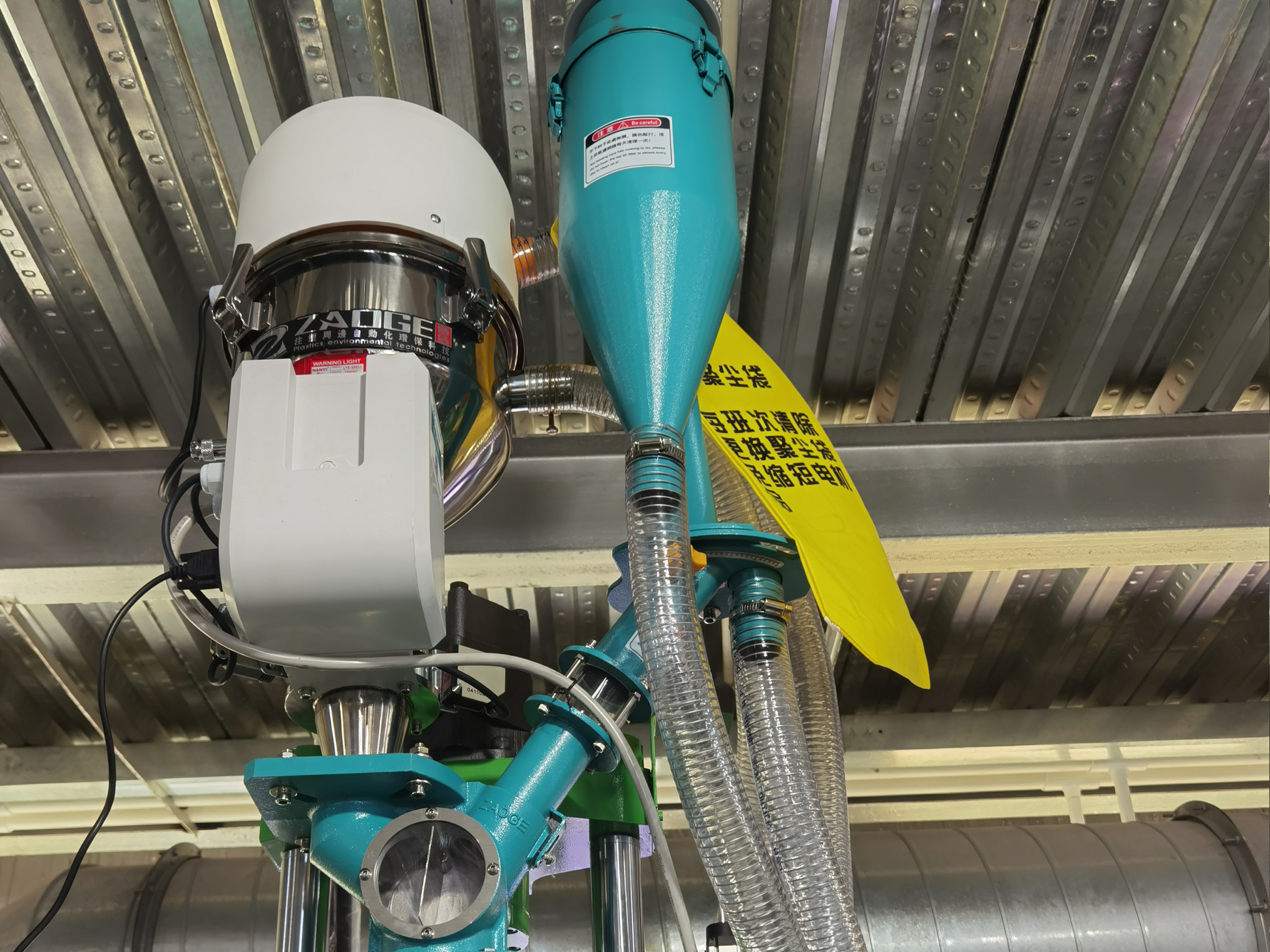

I-Vent Hole

Amanzi negesi yemfucuza ezintweni zokusetshenziswa kukhishwa ngembobo yokukhipha umoya, eyenza ukukhiqizwa kwamapulangwe epulasitiki ekhwalithi ephezulu ngesikhathi sokukhishwa. Isistimu yokumunca i-vacuum nayo iyatholakala njengesici ozikhethela sona.

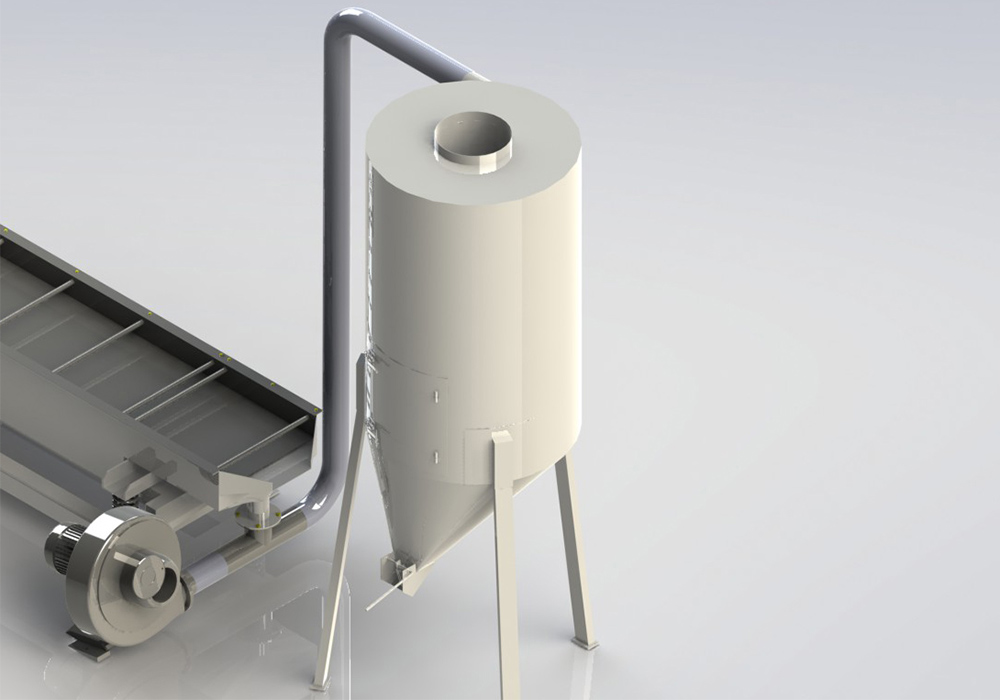

I-Dehydrator

Izinhlayiya zepulasitiki, kanye namanzi okupholisa avela ethangini lokupholisa lokusika ekhanda, faka indawo engaphansi ye-dehydrator. Ngokusebenzisa ama-centrifugal blades nezikrini ezingaphakathi kwe-dehydrator, amanzi ayinsalela ezinhlayiyeni angasuswa ngokuphelele.

I-Dehydrator

Izinhlayiya zepulasitiki, kanye namanzi okupholisa avela ethangini lokupholisa lokusika ekhanda, faka indawo engaphansi ye-dehydrator. Ngokusebenzisa ama-centrifugal blades nezikrini ezingaphakathi kwe-dehydrator, amanzi ayinsalela ezinhlayiyeni angasuswa ngokuphelele.

Ibhakede Elichotshozwayo

Uhlelo lwe-Changyi Machinery luchoboza amafilimu nezinto ezisemaphethelweni ezivela ezimbonini zamafilimu aphephuka umoya, lukhiqize ukushisa okomisa izinto ezimanzi. Inezifafazi zamanzi ezizenzakalelayo zokuyipholisa kanye nesistimu yokupholisa amanzi ukuvimbela ukugoqa lapho ushintsha ama-blade.

I-Die Face Plastic Granulator System

Ipulasitiki encibilikisiwe ikhishwa ekhanda ledayizi futhi isikwe ngama-blade ajikelezayo ngaphambi kokuwela iringi yamanzi ukuze ipholiswe. Uhlelo lunomklamo ozenzakalelayo wokubamba i-blade yezinhlayiya ezifanayo.

I-Die Face Plastic Granulator System

Ipulasitiki encibilikisiwe ikhishwa ekhanda ledayizi futhi isikwe ngama-blade ajikelezayo ngaphambi kokuwela iringi yamanzi ukuze ipholiswe. Uhlelo lunomklamo ozenzakalelayo wokubamba i-blade yezinhlayiya ezifanayo.

Izicelo Ze-Granulator

I-Plastic Fiber

Izikhwama zePlastiki ze-Hdpe

Indwangu Engalukiwe

Uziphu

Ifilimu

Igwebu

Imininingwane

| Uchungechunge lwe-ZGL | |||||||

| Imodi | I-ZGL-65 | I-ZGL-85 | I-ZGL-100 | I-ZGL-125 | I-ZGL-135 | I-ZGL-155 | I-ZGL-175 |

| Ukuchoboza amandla kamotha | 30HP | 60HP | 70HP | 100HP | 125HP | 175HP | 200HP |

| Ukusingatha amandla kamotha | 75hp | 75hp | 125HP | 175HP | 200HP | 250HP | 350HP |

| Iphoyinti lokulawula izinga lokushisa | Izingxenye ezi-6 (amapayipi wezinto ezi-4, isishintshi sesikrini esingu-1, nokukhipha oku-1) | Izingxenye ezi-6 (amapayipi wezinto ezi-4, isishintshi sesikrini esingu-1, nokukhipha oku-1) | Izingxenye ezi-6 (amapayipi wezinto ezi-4, isishintshi sesikrini esingu-1, nokukhipha oku-1) | Izingxenye eziyisi-8 (amapayipi abalulekile angu-6, isishintshi sesikrini esingu-1, nokukhipha oku-1) | Izingxenye eziyisi-8 (amapayipi abalulekile angu-6, isishintshi sesikrini esingu-1, nokukhipha oku-1) | Izingxenye eziyi-10 (amapayipi abalulekile angu-8, isishintshi sesikrini esingu-1, nokukhipha oku-1) | Izingxenye eziyi-10 (amapayipi abalulekile angu-8, isishintshi sesikrini esingu-1, nokukhipha oku-1) |

| Amandla | 80 ~ 100kg/h | 200 ~ 300kg/h | 300 ~ 400kg/h | 450-600kg/h | 550 ~ 700kg/h | 700~800kg/h | 800-1000kg/h |

| uhlelo lokupholisa ipayipi lempahla | Ukupholisa abalandeli | Ukupholisa abalandeli | Ukupholisa abalandeli | Ukupholisa abalandeli | Ukupholisa abalandeli | Ukupholisa abalandeli | Ukupholisa abalandeli |